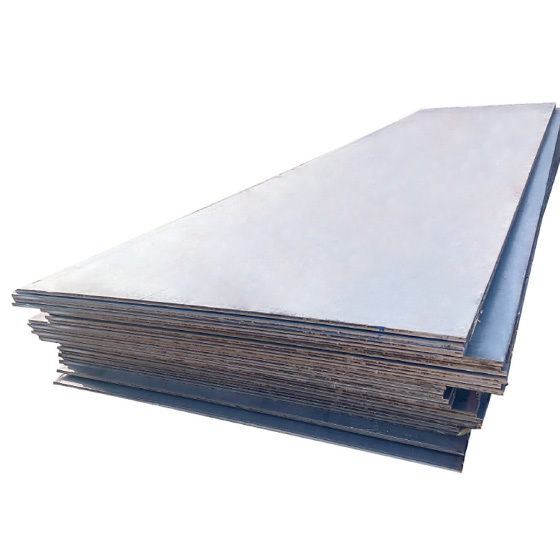

SPCC/SPCC/SPCD/SPCE Cold Rolled Steel Plate

SPCC cold rolled steel plate is a high-quality, low-carbon steel product known for its excellent surface finish, dimensional accuracy, and superior strength. Manufactured through the cold rolling process, SPCC steel plate provides improved formability and durability, making it ideal for precision applications. It is widely used in automotive, appliance manufacturing, and construction industries, where high-quality, smooth surfaces are essential. SPCC cold rolled steel plate offers outstanding weldability, making it suitable for various fabrication processes. This versatile material provides reliability and cost-effectiveness, ensuring long-lasting performance in a range of industrial applications. It meets industry standards for quality and performance.

Product Parameters

| Product Name | SPCC/SPCC/SPCD/SPCE Cold Rolled Steel Plate |

| Production Process | Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 100mm-3000mm |

| Length | 1m-12m, or Customized Size |

| Thickness | 0.1mm-400mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

SPCC Grade: C≦0.15; Mn≦0.60; P≦0.100; S≦0.035

SPCCT Grade: C≦0.15; Mn≦0.60; P≦0.100; S≦0.035

SPCD Grade: C≦0.10; Mn≦0.50; P≦0.040; S≦0.035

SPCE Grade: C≦0.08; Mn≦0.45; P≦0.030; S≦0.030

SPCF Grade: C≦0.06; Mn≦0.45; P≦0.030; S≦0.030

SPCG Grade: C≦0.02; Mn≦0.25; P≦0.020; S≦0.020

Mechanical Properties

Hardness: Heat Treatment Code HRBS HV10

Annealed A – –

Annealed + Finishing S – –

1/8 hard 8 50~71 95~130

1/4 hard 4 65~80 115~150

1/2 hard 2 74~89 135~185

Full hard 1 ≥85 ≥170

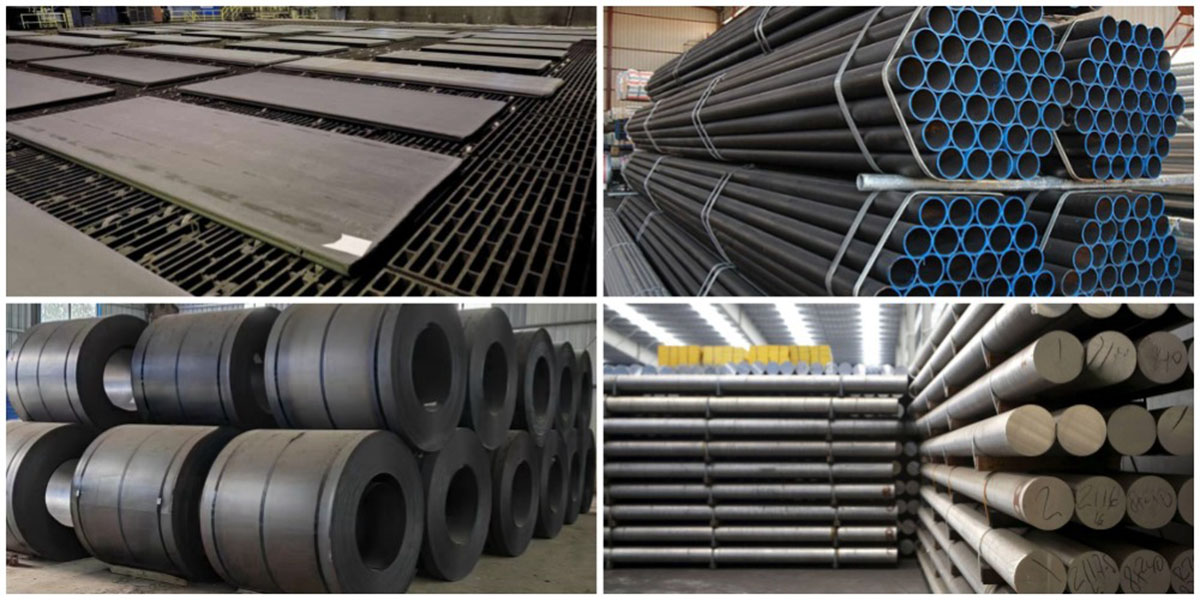

Scope of Application

SPCC/SPCCT: Common & General Use; Characteristics: Suitable for bending processing and simple deep drawing processing, is the most demand varieties; Applications: Refrigerators, rails, switchboards, iron baskets and so on.

SPCD: Drawing & Stamping Use; Characteristics: Second only to SPCE, is the quality of the smaller deviation of the drawing steel plate; Applications: Automobile chassis, roof and so on.

SPCE/SPCF: Deep Drawing & Stamping Use; Characteristics: Grain is adjusted, deep drawing performance is excellent, after the stamping can get a beautiful surface. Applications: Car fender, rear side panels and so on.

SPCG: Extra-Deep Drawing & Stamping & Punching Use; Characteristics: Very low carbon cold rolled steel, excellent deep drawing processability. Applications: Car interior board, surface and so on.

Remarks: SPCCT is users specified the grade of SPCC which need to ensure that the tensile strength and extensibility of the species. SPCF, SPCG will need to ensure that there have non-aging (not due to the occurrence of tensile deformation of the property), after outside factory for 6 months – that is, SPCC, SPCD, SPCE if stored for a long time, will produce mechanical performance changes, especially to reduce the cold stamping performance, it should be used as soon as possible.SPCC series catalog need to make provision for hardness and surface in advance when ordering.