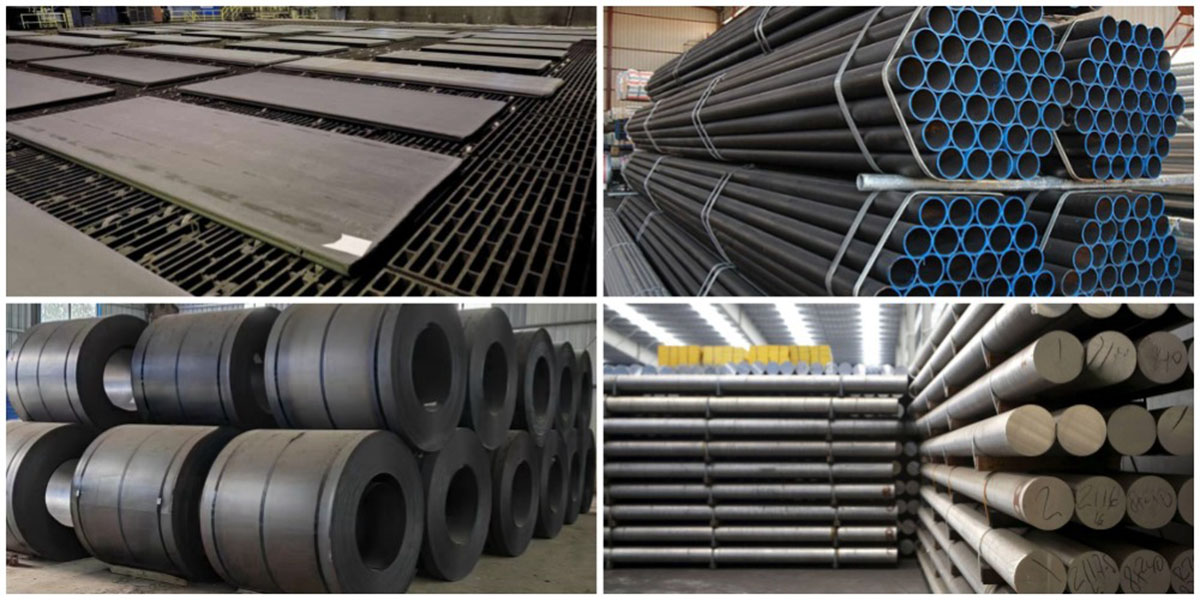

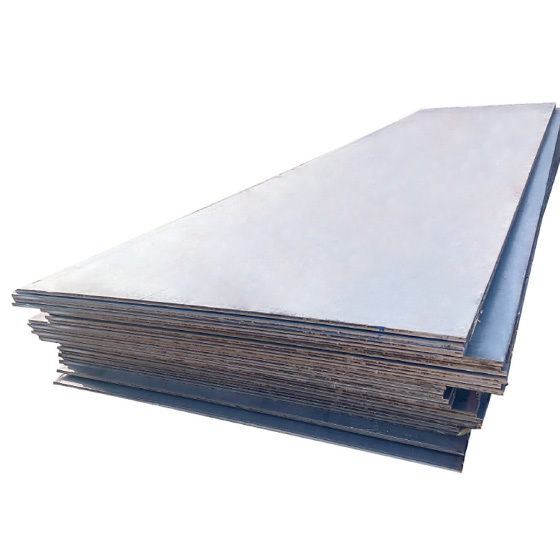

A53 Seamless & Welded Carbon Steel Pipe Description

A53 seamless and welded carbon steel pipe is a versatile and durable steel product widely used in construction, plumbing, and industrial applications. Known for its excellent strength and resistance to corrosion, it is ideal for use in transporting fluids and gases under moderate to high-pressure conditions. This pipe is available in both seamless and welded varieties, offering flexibility for different manufacturing needs. A53 carbon steel pipe meets industry standards for quality and performance, making it a reliable choice for a variety of projects. Its weldability and durability ensure long-lasting, cost-effective solutions for both residential and industrial systems.

Product Parameters

| Product Name | A53 Seamless & Welded Carbon Steel Pipe | |

| Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI etc. | |

| Outer Diameter | Seamless: 1/4″-36″ | Welding: 21.3mm-3620mm |

| Round Tube: 1/2″-10″ | Square Tube/Rectangular Tube: 15x15mm-400x600mm | |

| Wall Thickness | Seamless: 1.25mm-50mm | Welding: 1.65mm-65mm |

| Length | 3-12 meters, Support customization | |

| Surface Process | Bright, Polished, Black | |

| Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |

Chemical Composition

| A53 | Grade | C | Mn | P | S | Cu | Ni | Cr | Mo | V |

| Type S (Seamless) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Type E (Resistance Welding) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Type F (Furnace Welding) | A | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

Mechanical Properties

| A53 | Grade A | Grade B |

| Tensile Strength Min. psi (MPa) | 48,000 (330) | 60,000 (415) |

| Yield Strength Min. psi (MPa) | 30,000 (205) | 35,000 (240) |

Physical Performance

| Density 20°C Kg/dm³ | Modulus of Elasticity Kn/² mm | Coefficient of Thermal Conductivity 20°C W/m K |

Heat Capacity 20°C J/kg K |

Resistivity 20°C Ωmm²/m |

|||

| 20 C° | 300 C° | 400 C° | 450 C° | ||||

| 7.85 | 210 | 192 | 184 | 179 | 51 | 461 | 0.20 |

Scope of Application

Construction: underground pipeline, underground water, hot water transmission, mechanical processing, bearing sleeve, processing machinery parts, etc.

Electrical: natural gas transmission, hydroelectric fluid pipelines, anti-static pipes for wind farms, etc.