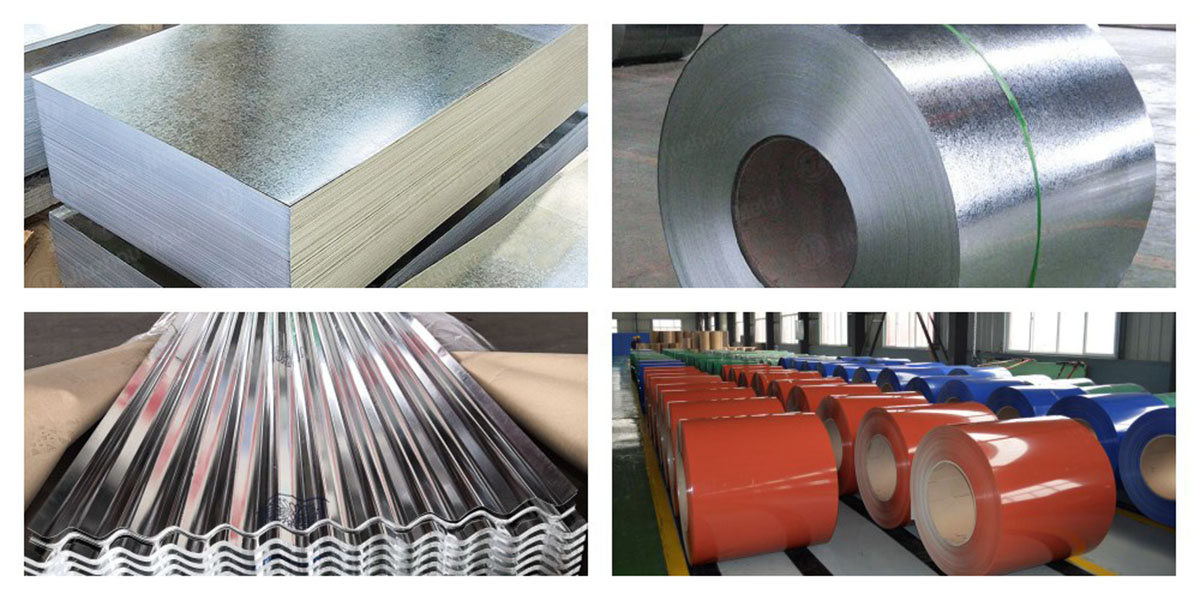

Galvanized Coil Description

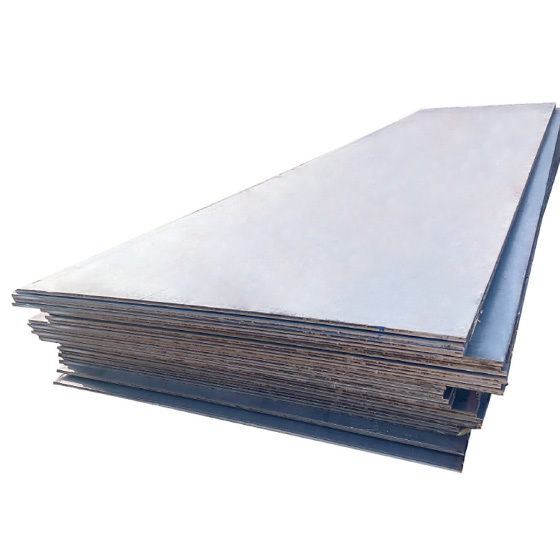

Galvanized coil is a high-quality steel product coated with a protective zinc layer through an advanced galvanization process, ensuring excellent corrosion resistance and durability. It is widely used in construction, automotive, home appliances, and industrial manufacturing due to its strength, formability, and weather resistance. The galvanized surface enhances adhesion for further processing, such as painting or profiling, meeting diverse industry requirements. Manufactured in compliance with international quality standards, galvanized coils provide long-lasting performance and cost-effective solutions. Designed for B2B customers, they offer reliability and efficiency for manufacturers, contractors, and industrial suppliers seeking high-performance steel materials for various applications.

Full cold galvanizing process:

Chemical degreasing → hot water washing → water washing → electrolytic degreasing → water washing → acid washing → rust removal → water washing → electrogalvanizing process → water washing → passivation → hot water washing → drying → quality inspection → packaging and sales

Scope of Application

Building Materials Field

Electrogalvanizing has a wide range of applications in the field of building materials. First of all, electro-galvanizing can be used to manufacture construction steel, which not only prevents metal oxidation and prolongs its service life, but also enhances the toughness, strength and corrosion resistance of steel, and improves the performance of steel. Secondly, in the decoration of building exterior walls, electro-galvanized aluminum alloy, electro-galvanized iron alloy and other materials are also widely used, which can protect the steel structure and prevent oxidation, but also has the characteristics of beauty and fire prevention.

Automobile Manufacturing Field

Electrogalvanizing is also a commonly used material in the field of automobile manufacturing. Electro-galvanized coating can be used for surface protection and repair of automobile parts to avoid oxidation corrosion and damage, and to improve the service life of automobiles. The electro-galvanized coating can also be used in the manufacture of parts such as car frames and casings to avoid oxidation and corrosion, and improve the overall quality and durability of the car.

Home Appliance Manufacturing Field

In the field of home appliance manufacturing, galvanizing also has its important applications. For example, the manufacture of refrigerators, washing machines and other household appliances shell, lining, refrigerator and other parts, usually need to use electro-galvanized material for surface coating, to prevent metal oxidation, improve appearance and performance.

Product Parameters

| Product Name | Galvanized Coil |

| Thickness | 0.12mm-3.5mm |

| Width | 600mm-1500mm |

| Length | 508mm/610mm, Support Customization |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| Zinc Layer | Hot Galvanizing: 60-275g/m² |

| Pre-galvanized: 80-275g/m² |

Chemical Composition

| Standard | Grade | C | Si | Mn | P | S | Ti |

| Forcold Forming

Chinese Standard |

DX51D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 |

| DX52D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX53D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX54D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX56D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| DX57D+Z | 0.12 | 0.50 | 0.60 | 0.100 | 0.045 | 0.30 | |

| Forcold Forming

Japanese Standard |

SGCC | 0.15 | 0.50 | 0.80 | 0.050 | 0.030 | 0.025 |

| SGCD1 SGCD2 |

0.12 0.10 |

0.50 0.50 |

0.60 0.45 |

0.040 0.030 |

0.030 0.030 |

0.025 0.025 |

|

| SGCD3 | 0.08 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| SGCD4 | 0.06 | 0.50 | 0.45 | 0.030 | 0.030 | 0.025 | |

| For Structure

Japanese Standard |

SGC340 | 0.25 | 0.50 | 1.70 | 0.200 | 0.035 | 0.025 |

| SGC400 SGC440 |

0.25 0.25 |

0.50 0.50 |

1.70 2.00 |

0.200 0.200 |

0.035 0.035 |

0.150 0.150 |

|

| SGC490 | 0.30 | 0.50 | 2.00 | 0.200 | 0.035 | 0.025 | |

| SGC510 | 0.30 | 0.50 | 2.50 | 0.200 | 0.035 | 0.025 | |

| For Structure

AISI Standard |

S220GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 |

| S250GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S280GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S320GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.025 | |

| S350GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 | |

| S550GD+Z | 0.20 | 0.60 | 0.70 | 0.100 | 0.045 | 0.150 |

Mechanical Properties

| Grade | Yield Strength MPa≥ | Tensile Strength MPa≥ | Elongation A%≥ |

| DX51D Z/ZM/AZ/AM | 240-380 | 270-500 | 22 |

| DX52D Z/ZM/AZ/AM | 140-300 | 270-420 | 26 |

| DX53D Z/ZM/AZ/AM | 140-260 | 270-380 | 30 |

| DX54D Z/ZM/AZ/AM | 120-220 | 260-350 | 36 |

| S220GD Z/ZM/AM | 220 | 300 | 20 |

| S250GD Z/ZM/AZ/AM | 250 | 330 | 19 |

| S280GD Z/ZM/AM | 280 | 360 | 18 |

| S300GD A/AM | 300 | 380 | 18 |

| S320GD Z/ZM/AM | 320 | 390 | 17 |

| S350GD Z/ZM/AZ/AM | 350 | 420 | 16 |

| S450GD A/AM | 450 | 480 | 15 |

| S550GD Z/ZM/AZ/AM | 550 | 550 | – |

| Use of The Environment | Recommended Zinc Thickness |

| Indoor Use | Z10 or Z12 (100g/㎡or 120g/㎡) |

| Suburbs | Z20 and Painting (200g/㎡) |

| Urban or Industrial Area | Z27 (270g/㎡) or G90 (US Standard) and painted |

| Coastal Area | Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

| Punch or Deep Drawing Application | Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

| Surface Treatment Type | Code | Features |

| Chromic Acid Treatment | C | Good corrosion resistance, suitable for bare state |

| Chromic Acid Treatment+Oiling | S | Good corrosion resistance |

| Phosphoric Acid Treatment (Including Sealing Treatment) | P | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling | Q | Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

| Phosphoric Acid Treatment (Excluding Sealing Treatment) | T | Have a certain corrosion resistance, good paint performance |

| Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling | V | Has a certain corrosion resistance, good paint performance, and prevent rust |

| Oiling | O | Prevent rust during transportation and storage |

| No Treatment | M | Suitable for immediate painting |

Material Comparison

| Chinese Standard | Japan Standard | European Standard |

| DX51D Z/DC51D Z (CR) | SGCC | DX51D Z |

| DX52D Z/DC52D Z | SGCD1 | DX52D With |

| DX53D Z/DC53D Z/DX54D Z/DC54D Z | SGCD2/SGCD3 | DX53D Z/DX54D Z |

| S220/250/280/320/350/550GD Z | SGC340/400/440/490/570 | S220/250/280/320/350GD Z |

| DX51D Z/DD51D Z (HR) | SGHC | DX51D Z |