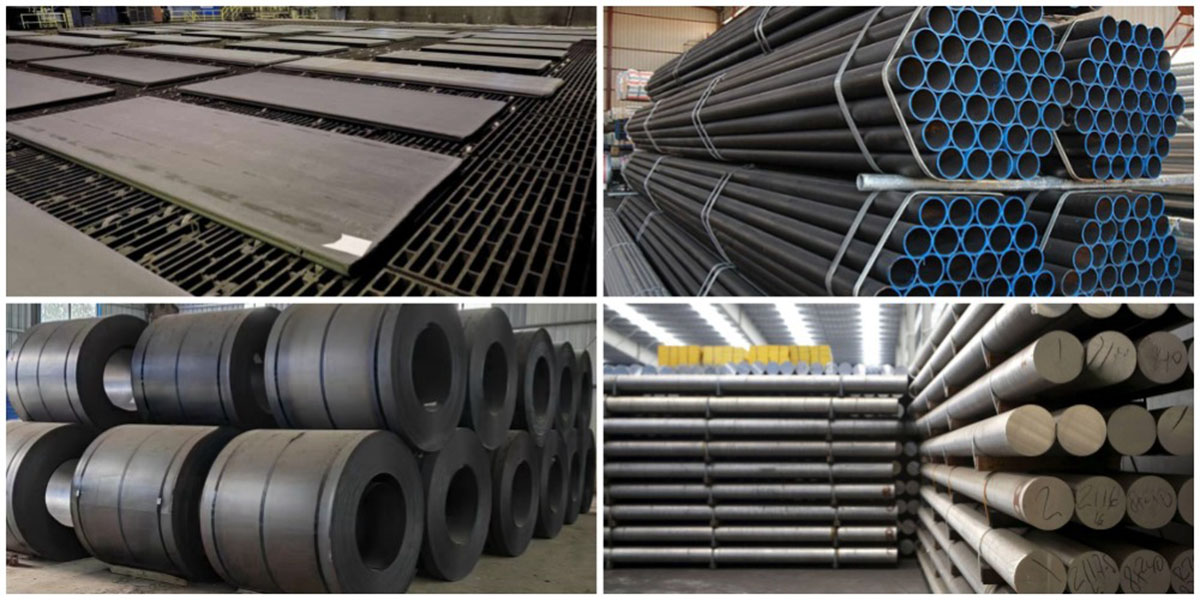

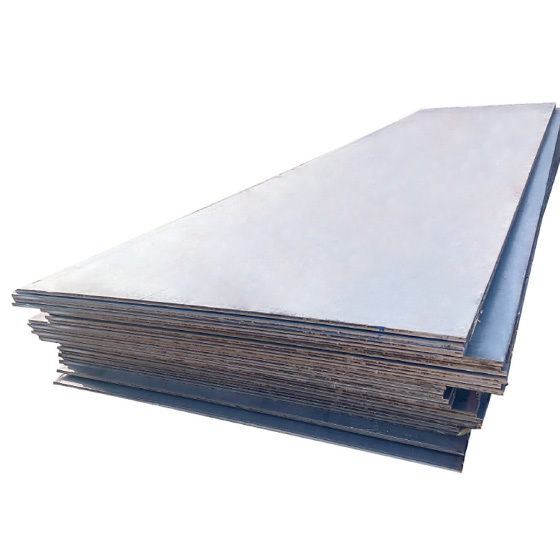

A335 Seamless Steel Pipe Description

A335 seamless steel pipe is a high-alloy steel product designed for high-temperature and high-pressure applications. Commonly used in industries such as power generation, petrochemical, and chemical, this steel pipe is known for its excellent strength, corrosion resistance, and durability. A335 seamless steel pipe can withstand extreme temperatures and is ideal for use in steam lines, heat exchangers, and boiler systems. It offers superior weldability and can be easily fabricated to meet specific project requirements. With reliable mechanical properties and long-lasting performance, A335 seamless steel pipe is a trusted choice for businesses in demanding industrial sectors.

Product Parameters

| Product Name | A335 Seamless Steel Pipe | |

| Standard | EN/DIN/JIS/ASTM/BS/ASME/AISI etc. | |

| Outer Diameter | Seamless: 1/4″-36″ | Welding: 21.3mm-3620mm |

| Round Tube: 1/2″-10″ | Square Tube/Rectangular Tube: 15x15mm-400x600mm | |

| Wall Thickness | Seamless: 1.25mm-50mm | Welding: 1.65mm-65mm |

| Length | 3-12 meters, Support customization | |

| Surface Process | Bright, Polished, Black | |

| Other Services | Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. | |

Chemical Composition

| A335 | UNS | C ≤ | Mn | P ≤ | S ≤ | Si ≤ | Cr | Mo |

| P1 | K11522 | 0.10-0.20 | 0.30-0.80 | 0.025 | 0.025 | 0.10-0.50 | – | 0.44-0.65 |

| P2 | K11547 | 0.10-0.20 | 0.30-0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.50-0.81 | 0.44-0.65 |

| P5 | K41545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 4.00-6.00 | 0.44-0.65 |

| P5b | K51545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.00-2.00 | 4.00-6.00 | 0.44-0.65 |

| P5c | K41245 | 0.12 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 4.00-6.00 | 0.44-0.65 |

| P9 | S50400 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 8.00-10.00 | 0.44-0.65 |

| P11 | K11597 | 0.05-0.15 | 0.30-0.61 | 0.025 | 0.025 | 0.50-1.00 | 1.00-1.50 | 0.44-0.65 |

| P12 | K11562 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 0.80-1.25 | 0.44-0.65 |

| P15 | K11578 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.15-1.65 | – | 0.44-0.65 |

| P21 | K31545 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 2.65-3.35 | 0.80-1.60 |

| P22 | K21590 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 1.90-2.60 | 0.87-1.13 |

| P91 | K91560 | 0.08-0.12 | 0.30-0.60 | 0.02 | 0.01 | 0.20-0.50 | 8.00-9.50 | 0.85-1.05 |

| P92 | K92460 | 0.07-0.13 | 0.30-0.60 | 0.02 | 0.01 | 0.5 | 8.50-9.50 | 0.30-0.60 |

Mechanical Properties

| A335 | UNS | Yield Strength Ksi | Tensile Strength Ksi | Elongation % |

| P1 | K11522 | 30 | 55 | 30 |

| P2 | K11547 | 30 | 55 | 30 |

| P5 | K41545 | 40 | 70 | 30 |

| P9 | S50400 | 30 | 60 | 30 |

| P11 | K11597 | 30 | 60 | 20 |

| P12 | K11562 | 32 | 60 | 30 |

| P22 | K21590 | 30 | 60 | 30 |

| P91 | K91560 | 60 | 85 | 20 |

Scope of Application

The specification covers “chrome-molybdenum” seamless pipes with excellent corrosion resistance and high temperature tensile strength. Generally, ASTM A335 P11, P22, and P91 pipelines are used for power generation and downstream oil and gas, and P5 and P9 grades are used for refinery applications.