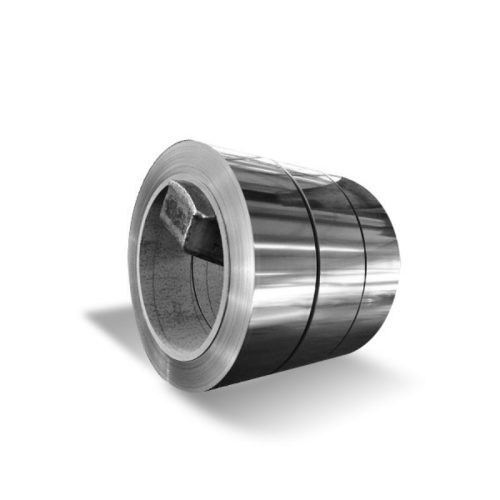

316L Stainless Steel Coil Description

316L stainless steel coil is a low-carbon, molybdenum-enhanced alloy known for its outstanding resistance to corrosion, particularly in chloride-rich environments. Its low carbon content reduces the risk of intergranular corrosion, making it ideal for welded applications in industries such as marine, chemical, and pharmaceutical. 316L stainless steel coil offers excellent strength, durability, and oxidation resistance at high temperatures, ensuring long-term performance in harsh conditions. It is highly resistant to pitting, crevice corrosion, and stress corrosion cracking. This coil is widely used for structural, industrial, and architectural applications, providing reliable, high-quality performance in demanding environments.

Product Parameters

| Product Name | 316L Stainless Steel Coil |

| Type | Steel Coil |

| Thickness | 2.5mm-10.0mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

| Width | 610mm-2000mm |

| Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

| Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

| Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging,

Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

| Certificate | ISO, SGS, BV, etc. |

| Production Technology | Hot Rolling, Cold Rolling |

| Edge Processing | Edging, Trimming |

Chemical Composition

| C | Si | Mn | Cr | Ni | S | P | Mo |

| ≤ 0.03 | ≤1.0 | ≤ 2.0 | 16.0~18.0 | 10.0~14.0 | ≤ 0.03 | ≤ 0.045 | 2.0~3.0 |

Mechanical Properties

| Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

| ≥480 | ≥177 | ≥ 40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

| Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

| 7.99 | 193 | 16.0 | 16.2 | 74 |