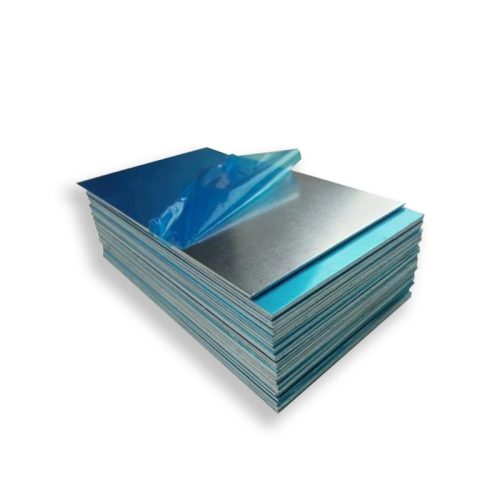

1060 Aluminum Plate Description

1060 aluminum plate is a high-purity, non-heat-treatable alloy known for its excellent corrosion resistance, superior electrical and thermal conductivity, and easy machinability. Containing 99.6% aluminum, it is widely used in industries like electrical, chemical, and food processing. This lightweight and durable aluminum plate is ideal for applications that require high performance in corrosive environments. It offers excellent weldability and formability, making it suitable for manufacturing heat exchangers, storage tanks, and various structural components. 1060 aluminum plate provides long-lasting performance, ensuring reliability in demanding industrial applications. Available in a range of sizes, it meets diverse manufacturing needs.

Product Parameters

|

Width |

20-3000mm or Customized |

Thickness |

0.1-120mm or Customized |

|

Length |

100-12000mm or Customized |

Certificate |

ISO, SGS, BV |

|

Standard |

JIS, AISI, ASTM, GB, DIN, EN, etc. |

||

|

Brand |

1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5754, 5A05, etc. 6000 Series: 6061, 6063, 6082, 6A02, etc. 7000 Series: 7050, 7475, 7075, etc. 8000 Series: 8A06, 8011, 8090, etc. |

||

|

Surface |

Coating, Embossing, Drawing, Polishing, Anodizing, etc. |

||

|

OEM Service |

Punching, Cutting Special Size, Making Flat Surface, Surface Treatment, etc. |

||

|

Delivery Time |

Received 30%, After deposit 7-15 working day |

||

|

Application |

Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware And Other Fields, etc. |

||

|

Sample |

Free Offers Sample |

||

|

Packaging |

Strapping, plastic bag, film, wooden pallet Standard seaworthy export packing or according to customer requirement |

||

Chemical Composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: Each |

Others: Total |

Al: Min. |

|

1050 |

0.25 |

0.40 |

0.05 |

0.05 |

0.05 |

– |

0.05 |

0.03 |

0.03 |

– |

99.50 |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

– |

0.05 |

0.03 |

0.03 |

– |

99.60 |

|

1070 |

0.20 |

0.25 |

0.04 |

0.03 |

0.03 |

– |

0.04 |

0.03 |

0.05 |

– |

99.70 |

|

1100 |

0.95 Si Fee |

0.05~0.20 |

0.05 |

– |

– |

0.1 |

– |

0.05 |

0.15 |

99.0 | |

|

2014 |

0.5~1.2 |

0.7 |

3.9~5.0 |

0.4~1.2 |

0.2~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Margin |

|

2017 |

0.2~0.8 |

0.7 |

3.5~4.5 |

0.4~1.0 |

0.4~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

91.5 – 95.5 |

|

2024 |

0.50 |

0.50 |

3.8~4.9 |

0.3~0.9 |

1.2~1.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Margin |

|

3003 |

0.60 |

0.70 |

0.05~0.20 |

1.0~1.5 |

– |

– |

0.10 |

– |

0.05 |

0.15 |

Margin |

|

3A21 |

0.60 |

0.70 |

0.20 |

1.0-1.6 |

0.05 |

– |

0.15 |

0.1-0.2 |

– |

– |

Margin |

|

3004 |

0.30 |

0.70 |

0.25 |

1.0~1.5 |

0.8~1.3 |

– |

0.25 |

– |

0.05 |

0.15 |

Margin |

|

3005 |

0.60 |

0.70 |

0.30 |

1.0~1.5 |

0.2~0.6 |

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

Margin |

|

3105 |

0.60 |

0.70 |

0.30 |

0.3~0.8 |

0.2~0.8 |

0.20 |

0.40 |

0.10 |

0.05 |

0.15 |

Margin |

|

5005 |

0.30 |

0.70 |

0.20 |

0.20 |

0.5~1.1 |

0.1 |

0.25 |

– |

0.05 |

0.15 |

Margin |

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

2.2~2.8 |

0.15~0.35 |

0.10 |

– |

0.05 |

0.15 |

Margin |

|

5754 |

0.40 |

0.40 |

0.10 |

0.50 |

2.6~3.6 |

0.30 |

0.20 |

0.15 |

0.05 |

0.15 |

Margin |

|

5A05 |

0.50 |

0.50 |

0.10 |

0.3-0.6 |

4.8-5.5 |

– |

0.20 |

– |

0.05 |

0.05 |

Margin |

|

5083 |

0.40 |

0.40 |

0.10 |

0.4~1.0 |

4.0~4.9 |

0.05~0.25 |

0.25 |

0.15 |

0.05 |

0.15 |

Margin |

|

6061 |

0.40~0.8 |

0.70 |

0.15~0.4 |

0.15 |

0.8~1.2 |

0.04~0.35 |

0.25 |

0.15 |

0.05 |

0.15 |

Margin |

|

6082 |

0.70~1.3 |

0.50 |

0.10 |

0.4~1.0 |

0.6~1.2 |

0.25 |

0.20 |

0.10 |

0.05 |

0.15 |

Margin |

|

7075 |

0.40 |

0.50 |

1.2~2.0 |

0.30 |

2.1~2.9 |

0.18~0.28 |

5.1~6.1 |

0.20 |

0.05 |

0.15 |

Margin |

Mechanical properties

| Tensile Strength

(MPa) |

Test Stress

0.2% (MPa) |

Elongation Rate D10

(%) |

| 110-136 | ≥75 | 3-5 |

Physical Performance

| Density | Melting Point | Modulus of Elasticity | Thermal Conductivity | Thermal Expansion |

| 2.7 Kg/m³ | 649 °C | 70-80 GPa | 234 W/m.K | 23.6× 10-6/K |

Annealing State

|

Brand |

Annealing State |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Scope of Application

|

Aluminum Uses And Application Area |

|

|

Food Packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Building |

Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

|

Transportation |

Auto parts, passenger car bodies, aviation ships and air cargo containers. |

|

Electronic Equipment |

Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

|

Consumer Goods |

Umbrellas, cooking utensils, sports equipment, etc |

|

Other |

Military, color coated aluminum plate, etc |